-

Understanding the social, technical and environmental implications of building is essential in today’s networked world. And developing solutions to the problems we have both caused and inherited is the responsibility of all. The Zumtobel Group Award – Innovations for Sustainability and Humanity in the Built Environmentencourages and promotes exactly that sense of responsibility and to reward innovative endeavour. In the run up to the announcement of the winners in September 2014, and in collaboration with Zumtobel AG, uncube is presenting, in series, the best of the shortlisted candidates in each of the award’s three categories: Initiatives and Applied Innovations, Buildings and Urban Developments.

Roden Crater image © James Turrell. (Photo: Florian Holzherr)

Part 1

-

In March 2013 the BIQ, a four storey residential building designed by SPLITTERWERK architects, was completed as part of the International Building Exhibition (IBA) in Hamburg. It showcases the first Solar-Leaf façade: a building integrated system absorbing CO2 emissions, while cultivating microalgae to generate biomass and heat as renewable energy resources. The environment for photosynthesis is provided by glass photobioreactors installed on the southwest and southeast elevations.

The façade utilises the bio-chemical process of photosynthesis for energy efficient buildings and building clusters. There are three main benefits: a) Generation of high-quality biomass for energetic use or as a resource for food and pharmaceutical industry (urban farming), b) generation of solar thermal heat and c) the use as a dynamic shading device. Cultivating microalgae in flat panel photobioreactors requires no additional land-use and is largely independent from weather conditions, allowing installations in urban environments. A floatation device harvests the BIQ’s algal biomass automatically. The carbon required to feed the algae is taken from a combustion process in proximity of the façade installation to implement a short carbon cycle, preventing carbon emissions to contribute to climate change. Microalgae contain high-quality proteins, vitamins and amino acids that make it a valuable resource for the food and pharmaceutical industry.

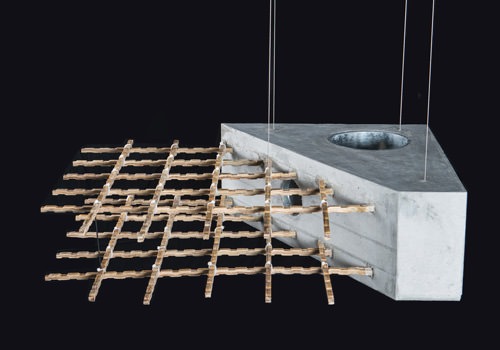

Newly developed bamboo composite materials as reinforcement systems in structural concrete have the potential to revolutionise the concrete building sector. Its advantages over steel are immense; higher tensile capacity, much lower production costs, lighter weight, anti-corrosion and natural renewability. It has the capacity to bind large amounts of CO2 due to bamboo’s fast growth; it is also easily accessible and available for production in developing territories.

At ETH Singapore’s Future Cities Laboratory (FCL) researchers are exploring new types of composite bamboo materials. Bamboo fibre is extracted and mixed with biological based adhesives. With the help of a hot press, a new material can be produced and moulded into a desired shape. It is water resistant, insect and fungi repellent and the mechanical properties such as thermal extension or ductility can be controlled. It can be used for specific applications that best take advantage of the material’s tensile strength, such as reinforcement systems in concrete or beams for ceilings and roof structures.

The Lowline will be the world’s first underground park, housed in a trolley terminal that has been vacant since 1948. Using next-generation solar technology and a new approach towards adaptive reuse. James Ramsey, the Lowline’s Co-Founder and Creator, developed a new solar technology system that captures sunlight above ground and funnels it underground through a system of optics. Once underground, the light is then re-distributed, using a reflective canopy, at an intensity that supports photosynthesis. This green technology will not only be a signature design feature of the Lowline, but will also serve as a model for how to light other underground and interior spaces, using solar energy.

The project’s design highlights the historical details of the space, while embracing innovation and the mechanisms of the technology.Category 1 – Applied Innovations

This category was introduced for the first time this year to help drive forward future developments. It includes innovative projects for application in, or around, buildings and urban infrastructure with approaches ranging from saving energy, using new materials or recycling, closed material and resource cycles to intelligent controls and software applications.

It opens up the field of the Zumtobel Group Award to interdisciplinary submissions from technical, research and engineering areas. Five finalists were shortlisted by the jury:

Photosynthesising Façade

Arup Deutschland GmbH for Solarleaf in Hamburg, Germany

This flat panel bioreactor building skin prototype makes rooftop vegetable gardens look prehistoric. The Solarleaf façade is a building-integrated system based on cultivating microalgae, which absorbs CO2 and generates heat and biomass as renewable resources.

High Fibre Futures

Future Cities Laboratory, Singapore / ETH Zurich, Switzerland

Bamboo’s advantages over steel are immense; higher tensile capacity, much lower production costs, lighter weight, anti-corrosion and natural renewability. This new research into bamboo composites could see it become the key reinforcement material of the future.

Subterranean Garden

James Ramsey, New York, USA

A project that uses next-generation solar technology to create an underground park in New York. This combination of optics and reflectors can generate enough light to sustain photosynthesis. If it works it could revolutionise urban public space worldwide.

-

About the Jury

The expert jury panel for the Zumtobel Group Award 2014 includes:

Kunlé Adeyemi – Architect & Urbanist / Founder NLÉ, Amsterdam (NL)

Yung Ho Chang – Architect / Studio FCJZ, Beijing (CN)

Brian Cody – Chair of the Institute of Buildings and Energy, Graz University of Technology (AT)

Winy Maas – Architect / MVRDV, Rotterdam (NL)

Ulrich Schumacher – CEO Zumtobel Group

Kazuyo Sejima – Architect / SANAA, Tokyo (JP)

Rainer Walz – Head of the Competence Center Sustainability and Infrastructure Systems at the Fraunhofer Institute for Systems and Innovation Research ISI in Karlsruhe

The evolution and development of prefab-rammed-earth technique has decisive benefits, which result in improved efficiency on-site. Regardless of the weather, scheduling is more reliable because drying takes place in a production hall.

Of particular note is the low energy footprint for the façade, which is about 90% lower than a conventional industrial façade. The material is partly the excavation material or locally sourced within a 10km radius. Building with earth is in itself sustainable, the material and human labour consumes minimal energy and can be recycled after dismantling, as it is not treated with any additives. The earth can be reused without degradation or energy intensive reprocessing, which makes the process genuine recycling, as opposed to standard down cycling. Despite the industrial prefabrication, a high degree of individuality can be achieved through detail work in the production hall, which allows a flexible and variable execution. Furthermore, it challenges creative conduction both architecturally and technically.

The KONE UltraRope is a new elevator hoisting technology that eliminates the disadvantages of conventional steel rope and opens up a world of possibilities in high-rise building design by enabling future elevator travel heights of 1 km, twice the distance currently feasible.

Comprised of a carbon fibre core and a unique high-friction coating, KONE UltraRope is extremely light, meaning elevator energy consumption in high-rise buildings can be cut significantly. The drop in rope weight means a dramatic reduction in elevator moving masses and therefore the benefits increase exponentially as travel heights increase. KONE UltraRope is resistant to wear and abrasion. Elevator downtime caused by building sway is also reduced as carbon fibre resonates at a different frequency to steel and most other building materials. Being carbon, the cable has an exceptionally long lifetime, at least twice that of conventional steel rope and with its special coating, no lubrication is required to maintain it.Category 1 – Applied Innovations

This category was introduced for the first time this year to help drive forward future developments. It includes innovative projects for application in, or around, buildings and urban infrastructure with approaches ranging from saving energy, using new materials or recycling, closed material and resource cycles to intelligent controls and software applications.

It opens up the field of the Zumtobel Group Award to interdisciplinary submissions from technical, research and engineering areas. Five finalists were shortlisted by the jury:

Higher and Higher

KONE, Espoo, Finland

A new ultra lightweight cable with a carbon core and unique high-friction coating to replace conventional steel cable, cutting weight, cost and maintenance. It’s makers claim the KONE Ultra-Rope will enable future elevator travel heights of up to a kilometre.

Prefab Rammed Earth

Lehm Ton Erde Baukunst GmbH, Schlins, Austria

Precast concrete has been around for over a century. Rammed earth for millennia. Combine the two and the result is a new building with a locally-sourced façade whose energy footprint is 90 per cent lower than a conventional industrial façade.

upcoming categories:

BUILDINGS

URBAN DEVELOPMENTS

&

INITIATIVESTHE WINNERS

will be announced in London on the 22nd September

and presented in the October issue of uncube

-

Search

-

FIND PRODUCTS

PRODUCT GROUP

- Building Materials

- Building Panels

- Building technology

- Façade

- Fittings

- Heating, Cooling, Ventilation

- Interior

- Roof

- Sanitary facilities

MANUFACTURER

- 3A Composites

- Alape

- Armstrong

- Caparol

- Eternit

- FSB

- Gira

- Hagemeister

- JUNG

- Kaldewei

- Lamberts

- Leicht

- Solarlux

- Steininger Designers

- Stiebel Eltron

- Velux

- Warema

- Wilkhahn

-

Follow Us

Tumblr

New and existing Tumblr users can connect with uncube and share our visual diary.

»Architectural interpretations accepted without reflection could obscure the search for signs of a true nature and a higher order.«

Louis Isadore Kahn

Keyboard Shortcuts

- Supermenu

- Skip Articles

- Turn Pages

- Contents