-

Molecular

Archi

tecture

Nanocarbons: the superheroes of materials science

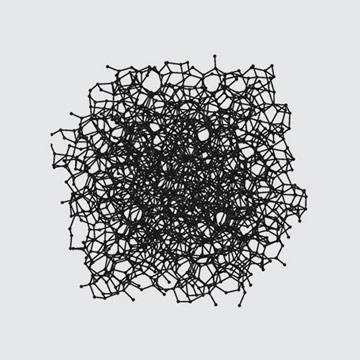

Transmission electron microscope (TEM) image of graphene nanoplatelets. (Image courtesy Cheap Tubes Inc)

-

Imagine a bullet-proof vest, as thin and flexible as a t-shirt, but stronger than steel and as hard as a diamond. It sounds like something straight out of a Marvel comic, but thanks to reports about recent advances in carbon nanotechnology, it may not be long before we can all suit up like superheroes.

While carbon is one of the most abundant materials on earth, it is nanotechnology that gives it its “super powers”, changing it from an ordinary material into one with extraordinary properties. Aside from being lightweight, it has some unique properties that make it an ideal nano-scale building block. By treating carbon atoms as molecular architecture components, scientists can change the element’s behaviour, allowing it to become super hard, super strong, and a superconductor of heat and electricity – and that’s just for starters.

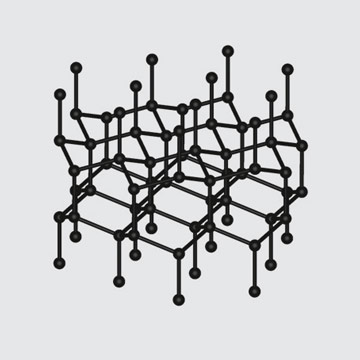

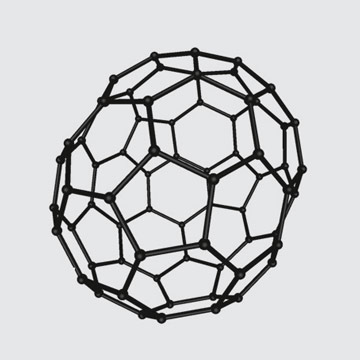

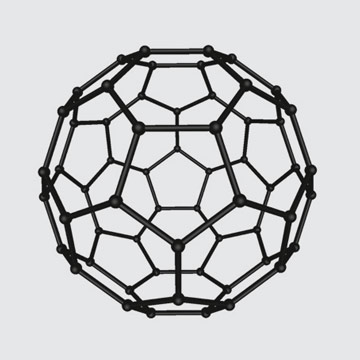

Carbon atoms can be arranged into geometric structures, creating atomic bonds that give it an entirely different range of attributes.

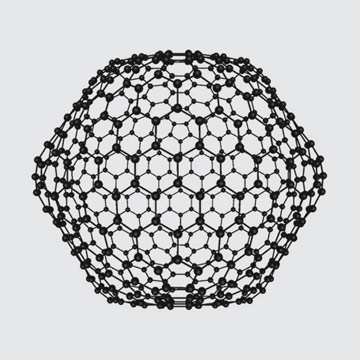

Carbon atoms arranged in architectural molecular structures: nanotubes, fullerenes, and graphene. (All images: Wikimedia Commons)

-

The tightly-knit molecular structure of a diamond, for example, makes it the hardest material known to man – quite the opposite of the soft and slippery graphite form found in a pencil. Graphene (a component of graphite) is a layer of carbon molecules just one atom thick arranged in a continuous hexagonal honeycomb lattice. This arrangement brings with it properties such as the conductivity of electricity and heat. The honeycomb structure also lends itself to three-dimensional geometric structures called fullerenes. In cylindrical form, these are known as carbon nanotubes and as spherical forms they are known by the delightfully termed “buckminsterfullerenes” or “buckyballs” after Buckminster Fuller’s geodesic dome structures.

Long chains of carbon nanotubes can be “grown” in a lab, atom by atom, each with the diameter of one nanometer, (one billionth of a meter, or about 50,000 times thinner than a strand of human hair). These microscopic threads are superconductors, meaning they can conduct electricity with almost no resistance and they are also magnetic, making them an ideal material for the electronics industry. By creating tiny circuits at the nano-scale, devices are able to store billions of times more data than the old silicon chips, allowing for our devices to get smaller and thinner every year. Carbon can also absorb enormous quantities of light (that’s why it’s black), so combined with superconductivity in this state it becomes an ideal material for absorbing sunlight on solar panels.

Nanocarbon’s super powers do not stop at electronics. Medical research has indicated that fullerenes may be able to reduce the size of tumours or even block the HIV virus. Further research projects involve trapping atoms inside of fullerenes to deliver medicine to cells, or to repair damaged DNA strands. Arranged in layers like Russian dolls, carbon nanotubes can also articulate as microscopic joints – with potential applications in nanorobotics. Buckypaper, 500 times stronger than steel and capable of conducting electricity, is a paper-thin layer of nanotubes that is currently under investigation for potential applications as a “skin” that could create energy, act as a circuit, and store data all in one.Scanning electron microscope (SEM) image of graphene foam made by researchers at I2CNER, Japan. (Image courtesy Stephen Lyth, © Jianfeng Liu, 2013)

-

So far, so superhero, but there are drawbacks. Very little is known about the potential dangers of carbon nanomaterials. Being so small, nanotubes and fullerenes are able to enter cell walls, and while this may have potentially positive medical applications, some studies show that nanotubes, at least, may have toxic effects similar to asbestos. Another big barrier is the high cost of production. Although it has dropped significantly, from around $1500 to $50 per gram in the last decade, nanotubes are still far from becoming a practical material for everyday use, so we may just have to wait a while for those supersuits after all.

(ssl)Cross section of a carbon nanotube fibre produced by Rice University and Teijin Aramid, taken with a scanning electron microscope (SEM). (Image: D. Tsentalovich/Rice University)

-

Search

-

FIND PRODUCTS

PRODUCT GROUP

- Building Materials

- Building Panels

- Building technology

- Façade

- Fittings

- Heating, Cooling, Ventilation

- Interior

- Roof

- Sanitary facilities

MANUFACTURER

- 3A Composites

- Alape

- Armstrong

- Caparol

- Eternit

- FSB

- Gira

- Hagemeister

- JUNG

- Kaldewei

- Lamberts

- Leicht

- Solarlux

- Steininger Designers

- Stiebel Eltron

- Velux

- Warema

- Wilkhahn

-

Follow Us

Tumblr

New and existing Tumblr users can connect with uncube and share our visual diary.

»Don‘t fight forces, use them.«

Richard Buckminster Fuller

Keyboard Shortcuts

- Supermenu

- Skip Articles

- Turn Pages

- Contents